D SERIES HYDRAULIC BREAKERS

Compact Range

- Building, renovation

- Landscaping, gardening

- Trenching

- Demolition, non-reinforced concrete

- General construction work

Medium & Heavy-duty Range

- Building and secondary breaking in quarry

- Site preparation, foundation works

- Road construction

- Demolition works, highly reinforced concrete

- Trenching

- Tunneling

- Bench leveling

- General construction works

FEATURES & BENEFITS

- Efficient gas and oil percussion system increase hitting power and reduces demand on the carrier’s hydraulic system

- Compatible with a wide range of operating pressure and oil flow

- Shock-mounted housing reduces noise and minimizes vibration transmitted to the carrier

- Two moving parts and minimal components decrease maintenance costs 15 models ranging from 200 to 13,645 ft/lb impact energy class

- Fits all Skid steer loaders, Tractor loaders, Backhoes, mini through large Excavators up to 60 tons

DemaRock D Series Breaker Specifications

| BREAKERS | MODEL | COMPACT RANGE | SKID STEER RANGE | MEDIUM RANGE | HEAVY-DUTY RANGE | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DESCRIPTION | UNIT | D40 | D45 | D53 | D68 | D75 | D85 | D100 | D125 | D135 | D140 | D155 | D165 | D175S | D185 | D200 | D210 | D248 |

| Impact Energy Class | ft/lbs | 200 | 350 | 400 | 750 | 1,000 | 1,200 | 2,000 | 3,000 | 4,000 | 5,000 | 7,500 | 8,500 | 12,000 | 12,170 | 20,282 | 16,964 | |

| Operating Weight | lbs | 225 | 284 | 397 | 796 | 994 | 1,616 | 2,220 | 3,023 | 4,255 | 4,511 | 6,543 | 6,559 | 8,602 | 10,582 | 13,153 | 15,432 | 24,251 |

| Operating Weight | kg | 102 | 129 | 180 | 361 | 451 | 733 | 1,007 | 1,371 | 1,930 | 2,046 | 2,968 | 2,975 | 3,902 | 4,800 | 5,966 | 7,000 | 11,000 |

| Required Oil Flow | gal/min | 4~7 | 5~8 | 6.6~13.2 | 10.5~18.5 | 13.1~23.6 | 15.8~26.3 | 21.1~29.1 | 23.7~31.7 | 38.3~47.6 | 31.7~47.6 | 47.6~63.4 | 52.8~65.6 | 52.8~68.42 | 58.08~71.28 | 75.4~88.6 | 79.4~100.5 | 118.9~132.1 |

| Required Oil Flow | ℓ/min | 15~25 | 20~30 | 25~50 | 40~70 | 50~90 | 60~100 | 80~110 | 90~120 | 145~180 | 120~180 | 180~240 | 200~250 | 200~260 | 220~270 | 285~335 | 300~380 | 450~500 |

| Operating Pressure | psi | 1,280~1,707 | 1,280~1,707 | 1,280~1,707 | 1,565~1,991 | 1,707~2,134 | 1,849~2,276 | 2,134~2,418 | 2,134~2,418 | 2,276~2,560 | 2,276~2,560 | 2,276~2,560 | 2,276~2,560 | 2,276~2,560 | 2,560~3129 | 2702~3129 | 2845~3414 | 2845~3414 |

| Operating Pressure | kg/cm2 | 90~120 | 90~120 | 90~120 | 110~140 | 120~150 | 130~160 | 150~170 | 150~170 | 160~180 | 160~180 | 160~180 | 160~180 | 160~180 | 180~220 | 190~220 | 200~240 | 200~240 |

| Impact Rate | bpm | 800~1,400 | 700~1,200 | 600~1,100 | 500~900 | 400~800 | 400~800 | 350~700 | 350~650 | 350~500 | 350~500 | 300~450 | 250~380 | 200~350 | 150~200 | 150~200 | 140~180 | 200~350 |

| Hose Diameter | in | 3/8, 1/2 | 3/8, 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 1 | 1 | 1 | 1¼ | 1¼ | 1¼ | 1¼ | 1¼ | 1¼ | 1½ |

| Tool Diameter | in | 1.6 | 1.8 | 2.1 | 2.7 | 3.0 | 3.3 | 3.9 | 4.9 | 5.3 | 5.5 | 6.1 | 6.5 | 6.9 | 7.3 | 7.87 | 8.3 | 9.8 |

| Tool Diameter | mm | 40 | 45 | 53 | 68 | 75 | 85 | 100 | 125 | 135 | 140 | 155 | 165 | 175 | 185 | 200 | 210 | 248 |

| Applicable Carrier Weight | lbs | 1,760~5,500 | 2,700~6,700 | 5,600~10,000 | 8,800~16,000 | 13,300~20,000 | 15,500~31,000 | 24,500~36,000 | 33,000~40,000 | 40,000~46,000 | 40,000~58,000 | 62,000~77,000 | 66,000~100,000 | 77,000~100,000 | 88,200~121,300 | 88,200~132,300 | 132,300~160,000 | 160,000~280,000 |

| Applicable Carrier Weight | ton | 0.8~2.5 | 1.2~3.0 | 2.5~4.5 | 4~7 | 6~9 | 7~14 | 11~16 | 16~21 | 18~26 | 18~26 | 28~35 | 30~45 | 35~45 | 40~55 | 45~60 | 60~80 | 80~140 |

| Noise Level | dB | 105.5 | 106.8 | 108.5 | 108.7 | 114.5 | 112 | 113.5 | 115 | 120 | 118 | 123 | 124 | 125 | – | – | – | – |

| Length | in | 42 | 49 | 53 | 66 | 67 | 83 | 94 | 102 | 106 | 111 | 127 | 134 | 147 | 155 | 159 | 169 | 189 |

| Length | mm | 1086 | 1235 | 1344 | 1684 | 1706 | 2120 | 2387 | 2,682 | 2,813 | 3,063 | 3,392 | 3,475 | 3,812 | 3,945 | 4,034 | 4,288 | 4,800 |

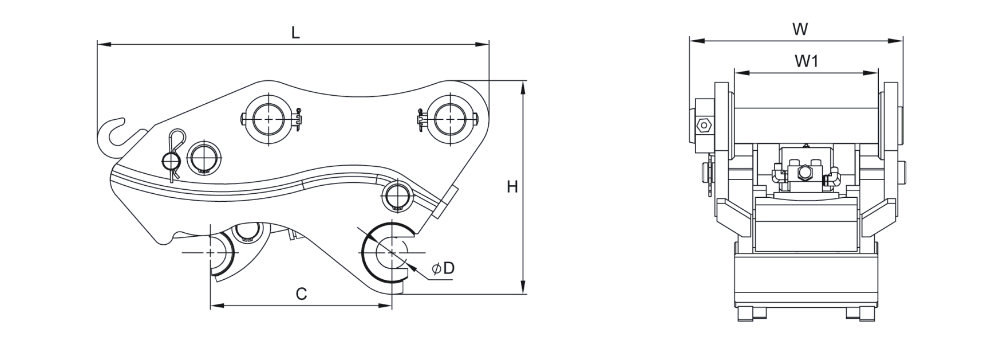

QC SERIES QUICK COUPLERS

DemaRock Hydraulic Quick Couplers are compatible with many makes and models of excavators. The perfect quick coupler to compliment your DemaRock attachments.

DemaRock QC Series Specifications

| Contents | Unit | 02QC | 03QC | 05QC | 08QC | 12QC/15QC | 20QC | 25QC | 35QC | 45QC |

|---|---|---|---|---|---|---|---|---|---|---|

| Overall Length (L) | mm | 370~420 | 400~450 | 550~590 | 610~650 | 800~860 | 1000~1050 | 1080~1150 | 1150~1250 | 1250~1350 |

| Overall Height (H) | mm | 255~300 | 230~280 | 300-380 | 310~390 | 415~510 | 500~580 | 550~615 | 595~650 | 600~660 |

| Overall Width (W) | mm | 150~200 | 210~250 | 240~310 | 300~385 | 360~420 | 450~560 | 530~640 | 580~650 | 630~700 |

| Pin Centre C | mm | 85~180 | 170~245 | 245~300 | 290~360 | 350~420 | 400~510 | 500~580 | 570~600 | 590~650 |

| Arm Width W1 | mm | 90~120 | 110~160 | 150~230 | 220~280 | 250~320 | 300~390 | 350~420 | 400~450 | 450~500 |

| Pin Diameter (φD) | mm | 25~30 | 35~40 | 45 | 50~55 | 60~70 | 80~85 | 90~95 | 100~110 | 110~130 |

| Offset Height (H1) | mm | 199 | 170 | 210 | 220 | 260 | 295 | 325 | 355 | 360 |

| Operating Pressure | bar | 30~150 | 30~150 | 30~150 | 30~150 | 30~150 | 30~200 | 30~200 | 30~200 | 30~200 |

| Oil Flow | L/min | 10~30 | 10~30 | 10~30 | 10~30 | 10~30 | 10~30 | 10~30 | 10~30 | 10~30 |

| Weight | kg | 20~30 | 35~50 | 60~80 | 90~120 | 200~260 | 340~380 | 530~580 | 700~760 | 750~850 |

| Applicable Excavator | ton | 1~2 | 2.5~4 | 5~6 | 7~10 | 11~17 | 18~26 | 26~35 | 36~40 | 40~50 |

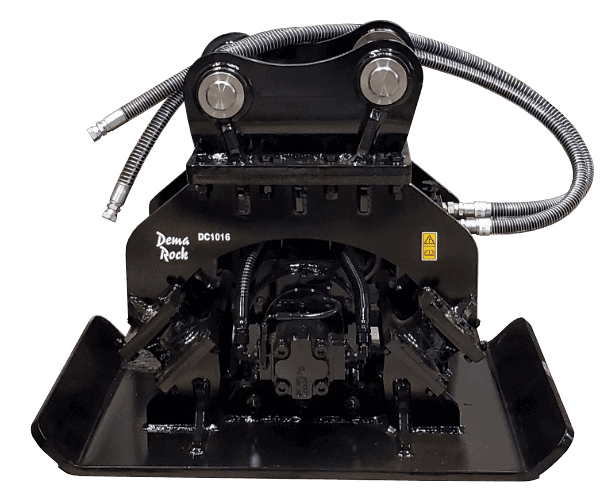

DC SERIES COMPACTORS

DemaRock Compactors are high-quality hydraulic material compactors at an affordable price. Robotic manufacturing processes and quality parts are used to manufacture DemaRock Compactors, so they are built to last. Comes in various sizes and power outputs which can be coupled with specialty top-mounts on request so that it’s easier to switch between attachments at the job site for the machine operators.

These compactors feature through-bolted frames for maximum frame strength, heavy-duty hydraulic cylinders with a spring return mechanism for even wear, and a powder-coated paint system to protect against rust and corrosion. Oiling systems are built into the compactors to provide long-lasting working hours and keep the job-site humming.

DemaRock DC Series Compactor Specifications

| Model | Vibration Frequency (vpm) | Working Flow (L/min) | Working Pressure (bar) | Impulse Force (kN) | Operating Weight (kg) | Carrier Weight (tonne) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| DC0103 | 2700 | 30~40 | 40~100 | 20 | 192 | 1~5 | 640*420*16 |

| DC0104 | 2700 | 60~70 | 90~130 | 35 | 380 | 2~4 | 900*550*20 |

| DC0410 | 2000 | 50~80 | 90~130 | 40 | 480 | 4~10 | 900*550*25 |

| DC0710 | 2200 | 70~90 | 100~140 | 40 | 380 | 6~10 | 900*550*25 |

| DC1016 | 2000 | 80~120 | 100~140 | 80 | 780 | 10~16 | 1200*750*25 |

| DC1116 | 2200 | 80~100 | 110~150 | 56 | 560 | 11~16 | 1200*750*25 |

| DC1723 | 2200 | 120~180 | 150~180 | 80 | 880 | 17~23 | 1350*900*30 |

| DC1724 | 2000 | 100~170 | 150~180 | 150 | 1080 | 17~24 | 1350*900*30 |

| DC2540 | 2000 | 120~210 | 120~210 | 160 | 1180 | 24~35 | 1350*900*30 |

DSG DWG SERIES GRAPPLES

DSG-Series Grapples

DWG-Series Grapples

DemaRock DSG Series & DWG Series Grapple Specifications

| Model | Opening Width (mm) | Total Weight (kg) | Closed Working Pressure (kg/cm2) | Closed Working Flow (lpm) | Rotating Working Pressure (kg/cm2) | Rotating Work Flow (lpm) | Unload Weigh (kg) | Suitable Carrier (ton) |

|---|---|---|---|---|---|---|---|---|

| DSG0406 | 1300 | 300 | 110~140 | 170 | 170 | 30~55 | 1500 | 4~6 |

| DSG0611 | 1400 | 360 | 120~160 | 180 | 180 | 50~100 | 2000 | 6~11 |

| DSG1216 | 1800 | 720 | 150~170 | 190 | 190 | 90~170 | 3000 | 12~16 |

| DSG1724 | 2300 | 1335 | 160~180 | 100~140 | 200 | 100~140 | 5000 | 17~23 |

| DSG2430 | 2500 | 1650 | 160~180 | 130~170 | 210 | 130~170 | 8000 | 25~30 |

| DWG0406 | 1300 | 315 | 110~140 | 30~55 | 170 | 30~55 | 1500 | 4~6 |

| DWG0611 | 1400 | 390 | 120~160 | 50~100 | 180 | 50~100 | 2000 | 6~11 |

| DWG1216 | 1800 | 740 | 150~170 | 90~110 | 190 | 90~110 | 3000 | 12~16 |

| DWG1724 | 2300 | 1380 | 160~180 | 100~140 | 200 | 100~140 | 5000 | 17~23 |

| DWG2430 | 2500 | 1700 | 160~180 | 130~170 | 210 | 130~170 | 8000 | 24~30 |